With Nvidia planning to use the AI, robotics and digital twin technologies it has touted as key to its future to ‘design and operate’ new U.S. factories for AI supercomputers, the country will get a front-row seat to Jensen Huang’s vision of industrial automation and digitalization.

While Nvidia said on Monday that its plan to produce AI supercomputers in the United States will create “hundreds of thousands of jobs,” the company said it will also rely on the AI, robotics and digital twin technologies it has touted as key to its future to “design and operate” new U.S. factories with its manufacturing partners for these products.

This means that the U.S. will soon get a front-row seat to Nvidia CEO Jensen Huang’s vision of industrial automation and digitalization, which includes humanoid robots that he views as necessary to address a growing shortage of human workers across the globe.

[Related: How Dell, Lenovo And Supermicro Are Adapting To Nvidia’s Fast AI Chip Transitions]

In Nvidia’s Monday announcement, the Santa Clara, Calif.-based company said that it has “commissioned more than a million square feet of manufacturing space to build and test Nvidia Blackwell chips in Arizona and AI supercomputers” in partnership with Taiwanese manufacturing partners TSMC, Foxconn and Wistron.

Blackwell production has already begun at TSMC’s chip fabrication plants in Phoenix, according to Nvidia. The AI supercomputer manufacturing plants, on the other hand, are being stood up by Foxconn in Houston and by Wistron in Dallas, with mass production “expected to ramp up in the next 12-15 months.”

The company said it is also working with Amkor and SPIL to handle the chip packaging and testing needs of its products.

Nvidia said the new production capacity will allow Nvidia to produce up to $500 billion of AI infrastructure in the U.S. within the next four years.

With Nvidia’s Automation Focus, A Question On Factory Jobs Lingers

President Trump’s administration on Monday hailed Nvidia’s investment in domestic production as validation of his push to bring manufacturing jobs back to the U.S. by imposing tariffs on various goods coming from the rest of the world.

However, an Nvidia spokesperson declined to provide any clarity about the “hundreds of thousands of jobs” it expects will be created with this move, including how many of those roles will be temporary construction jobs versus permanent manufacturing jobs.

A senior executive at a top Nvidia partner told CRN that he expects these new U.S. factories run by Foxconn and Wistron “will create a lot of jobs,” but those roles will be different than the types of jobs that existed 20 years ago because of how robotics and other technologies are changing the way manufacturing plants are designed and operated.

“If you are going to build simulations, you’re going to have robotics, you need people who can service those things, who can run the simulations, who understand the throughput of the business and the process, even if there’s not as much manual labor,” said Andy Lin, CTO and vice president of strategy and innovation of Houston-based Mark III Systems, which won Nvidia’s Software Partner of the Year award this year.

With Nvidia’s manufacturing partners set to use the company’s AI, robotics and digital twin technologies for these new facilities, Lin said he expects these plants to serve as showcases of what Nvidia hopes will become standard across the industry.

“Reading between the lines. I think it’s a great opportunity for them to have a marketing showcase. I could see them doing a lot of tours in the years ahead, showing other organizations how they do things,” he said.

Jensen Huang Says ‘The Time Has Come For Robots’

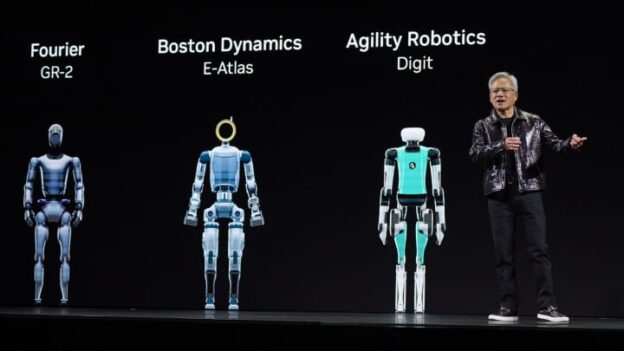

At Nvidia’s GTC 2025 event last month, Huang outlined his vision for industrial automation and digitalization—which he calls “physical AI”—and demonstrated how the AI infrastructure giant’s chips, compute platforms, AI models and software will enable a new level of capabilities for robots and automated manufacturing environments.

The move is part of Huang’s strategy to create new markets that will drive demand for Nvidia’s GPUs and associated platforms, which are used to power a wide range of AI workloads. This has paid off well so far for Nvidia, whose revenue more than doubled last year to $130.5 billion.

“The time has come for robots,” he declared in his GTC keynote in March, pointing to a looming labor shortage as a prime reason.

“We know very clearly that the world has [a] severe shortage of human laborers, human workers. By the end of this decade, the world is going to be at least 50 million workers short,” Huang said. “We’d be more than delighted to pay them each $50,000 [a year] to come to work. We’re probably going to have to pay robots $50,000 a year to come to work, and so this is going to be a very, very large industry.”

Two of the technologies Huang touted as part of this physical AI vision are ones that Nvidia said on Monday will be key to the AI supercomputer factories that its manufacturing partners Foxconn and Wistron will build in Texas.

In fact, Foxconn and Wistron, who have long championed automation and digital transformation, have already been using one of these technologies, Nvidia Omniverse, among others, for factories elsewhere across the world.

While they aren’t the first companies that plan to use Nvidia’s AI infrastructure products to modernize manufacturing in the U.S., they will likely be the highest-profile examples because of the strategic importance of AI infrastructure to the country.

“Obviously, the usage of Omniverse and digital twins and robotics is really strategic for Nvidia,” said Lin, the executive at Nvidia partner Mark III. “They’re eating their own dog food here because smart manufacturing is one of the mega-trends.”

Wistron Uses Omniverse To Optimize DGX System Testing

Omniverse is an expansive collaboration software platform for building 3-D applications that can be used to create digital twins, or virtual representations, of real-world factory environments. More recently, Nvidia has referred to Omniverse as the “operating system for physical AI.”

The digital twins created in Omniverse rely on live data from IoT sensors and devices in these factories, and they can be used to, among many other things, simulate changes in various manufacturing processes before the adjustments are made in the real world.

For instance, Wistron built a digital twin platform using Omniverse to improve the energy efficiency and productivity of the run-in test rooms it uses to test the reliability, quality and safety of Nvidia’s DGX and HGX products it manufactures. This was detailed in a blog post that was published by Nvidia last year.

Relying on real-time sensor data from its physical facilities, Wistron is using its GPU-accelerated digital twin platform to perform computational fluid dynamics simulations significantly faster than it can with traditional tools so that it can make “accurate predictions of temperature distributions and thermal behaviors” within the run-in test rooms.

These simulations—which also benefit from Nvidia’s PhysicsNeMo framework for creating “physics-informed AI models”—are helping Wistron, in turn, improve the thermal dynamics of its run-in test rooms and “reduce risks in their facilities.” This could result in a potential reduction in energy consumption by 10 percent, according to Nvidia.

Foxconn Uses Omniverse, Other Nvidia Tech To Train Robots

Foxconn, the world’s largest electronics manufacturer, is expected to open a $900 million assembly plant in Mexico early next year for servers using Nvidia’s Grace Blackwell GB200 Superchip, Bloomberg reported this month.

In preparation, Foxconn’s engineers have been “defining and training robots” in a digital twin of the facility before it’s operational so that the “physical plant can produce at high efficiency” these Nvidia compute platforms, Nvidia detailed in a June 2024 blog post.

“Our digital twin will guide us to new levels of automation and industrial efficiency, saving time, cost and energy,” Foxconn Chairman Young Liu was quoted as saying by Nvidia.

Key to Foxconn’s plan to train robots with digital twins is Nvidia’s Omniverse platform.

The company is using Omniverse in conjunction with Siemens’ Xcelerator applications, including Teamcenter for product lifecycle management, through API integration to “design robot work cells and assembly lines,” according to Nvidia.

Foxconn is then using Omniverse to pull all the 3-D assets for robots and assembly lines into “one virtual factory where their robots will be trained” with Nvidia’s Isaac Sim, which is a reference application for simulating and testing AI-driven robotics solutions in “physically based virtual environments,” according to Nvidia.

“A growing set of manufacturers is building digital twins to streamline factory processes. Foxconn is among the first to take the next step in automation — training their AI robots in the digital twin,” Nvidia wrote in the June 2024 blog post about Foxconn.

Nvidia said it also has software solutions for training different kinds of robots in physical settings, whether that’s Isaac Manipulator for AI-enabled robot arms or Isaac Perceptor for robots that move autonomously within unstructured spaces.

Humanoid Robots To Help Make AI Supercomputers In US

The next major step in Nvidia’s robotic capabilities is Isaac GR00T, which is a software development platform the company announced last year for accelerating humanoid robotics research and development.

The AI infrastructure giant said on Monday that Isaac GR00T will be used to “build robots to automate manufacturing for the new U.S. factories being built by Foxconn and Wistron.

At Nvidia’s GTC event last month, the company announced the availability of training data and task evaluation scenarios for GR00T N1, which it called the “world’s first open, fully customizable foundation model for generalized humanoid reasoning and skills.”

“GR00T N1 features a dual-system architecture for thinking fast and slow, inspired by principles of human cognitive processing,” Huang said in his GTC keynote.

“The slow-thinking system lets the robot perceive and reason about its environment and instructions and plan the right actions to take. The fast-thinking system translates the plan into precise and continuous robot actions,” he added.

A Wednesday report released by global consulting firm Bain and Company said that humanoid robots “are approaching cost parity with human labor,” adding that automatons are “poised to take on physical jobs across industries within the next five years.”

Physical AI Will Create Opportunities For The Channel

Lin, the executive at Nvidia partner Mark III, said manufacturers who embrace Nvidia’s physical AI vision will create new opportunities for the channel, particularly around digital twin simulation, as enabled by Omniverse, and the infrastructure it requires.

“That’s been a trend that’s been going on for a while around IoT devices and operating technology out in the field,” he said. “These simulations thrive on data and data that [is] generated in the place of work in the real world, so that’ll just continue to reinforce that trend as manufacturing gets modernized in the U.S.”

However, Lin said, many of the manufacturing customers his company is working with are “very early” in their adoption of Omniverse and digital twins.

Once they set up fully fledged digital twins of their factories, these customers can start training robots in Omniverse simulations, so that they can “get robots out in the field faster” without having to test in the brick-and-mortar world,” according to Lin.

“That’s a huge growth area that I think increasing modern manufacturing in the U.S. will only help serve as a catalyst for,” he said.

But this will ultimately “depend on the culture of each manufacturing company,” Lin added. “Have they put the time in over the last five to 10 years to build a strong innovation capability that can move at a faster pace and prototype and try things out?”

https://www.crn.com/news/internet-of-things/2025/analysis-us-to-get-front-row-seat-to-nvidia-s-industrial-automation-vision